STS Crane Damage and Business Interruption: A Port's Critical Challenge

Crane downtime within a port can create significant disruption in both the short and long term. Breakdowns and damage of shore-based cranes can occur as a result of poor maintenance, operator errors, extreme weather events, and vessel contacts. These incidents can severely impact port operations, terminal throughput and efficiency, making it essential to minimise any crane downtime as much as possible.

The Evolution and Vulnerability of STS Cranes

The growth in the size of cargo and container vessels over the past 50 years has led to the development of larger shore-based cranes. These modern cranes, fabricated using more slender steel sections, can be susceptible to long-term issues such as fatigue and cracking. Regular inspections and monitoring are crucial for identifying early signs of wear and preventing prolonged operational downtime.

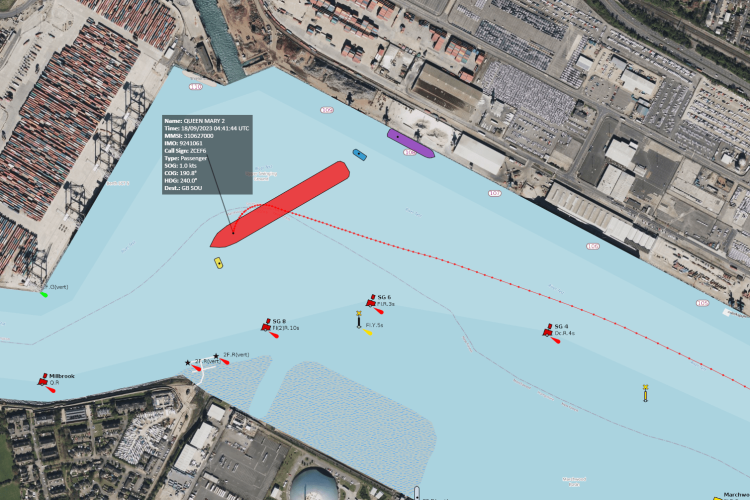

Whilst STS cranes have the structural capability to reliably lift cargo on and off vessels, their geometry makes them vulnerable to deformation and buckling if they are contacted by a vessel during berthing or unberthing. Such incidents can lead to expensive repairs, significant component replacements, or, in the worst cases, the catastrophic collapse of the crane(s).

The Importance of Rigorous Inspections

Under the Lifting Operations and Lifting Equipment Regulations (LOLER), cranes must undergo detailed inspections every six to twelve months to ensure they are in safe operational condition. These inspections assess all structural, mechanical, and electrical aspects of the crane, providing valuable insights into short-term maintenance requirements and planning for future capital upgrades.

Types and Extent of Crane Damage

In the event of vessel contact damage, an inspection of the crane by a qualified and experienced engineer as soon as possible, is important.

Depending on the point of contact, crane damage can range from minor dents and localised buckling of the crane leg structures to severe deformation, twisting and buckling to the whole crane structure. With significant contact, derailment of the crane bogies can occur. Depending on the severity of the damage, temporary works such as propping, stabilisation, or anchoring of the crane might be required to prevent collapse, especially in terminals exposed to strong winds and tropical monsoons.

Assessing damage accurately and exploring all the repair options, is very important in the early stages. This includes the possibility of in-situ repairs. Specialist contractors can often work with terminal operators and crane manufacturers to perform on-site repairs, minimising downtime and preserving operational warranties. The decision to repair or replace the crane (or the damaged component) depends on a careful assessment of the repair costs, disruption to the terminal, and the overall time required for completion.

Managing Business Interruption

Terminal revenue relies heavily on crane productivity and efficiency. A crane breakdown or damage incident causes immediate disruption and reduces terminal throughput, making it essential to record operational disruption data accurately. Evaluating the scale of disruption and the effectiveness of the terminal’s mitigation measures is an important part of evaluating any subsequent claim.

Each disruption incident is unique, requiring a tailored approach based on the complexity and scale of the affected operations. Experience in terminal development and operation is therefore key to accurately assessing a business interruption claim.

Waves Group’s Capability

Here at Waves Group, we have a team of six experienced crane consultants and experts located around the globe, ready to assist at a moment’s notice. We provide specialist advice to vessel owners, terminals, P&I Clubs, insurers and lawyers related to causation investigation, assessing damage and mitigating against further losses.

Our comprehensive, targeted personalised approach contributes to the quick and efficient evaluation of an incident and assists in identifying key issues that must be addressed so as to minimise disruption to terminal and vessel operations alike.

For further information on how we can assist with your crane damage and business interruption claims, please contact Rob Williams or any member of the team on +44 (0) 20 7083 7266 or by email [email protected].